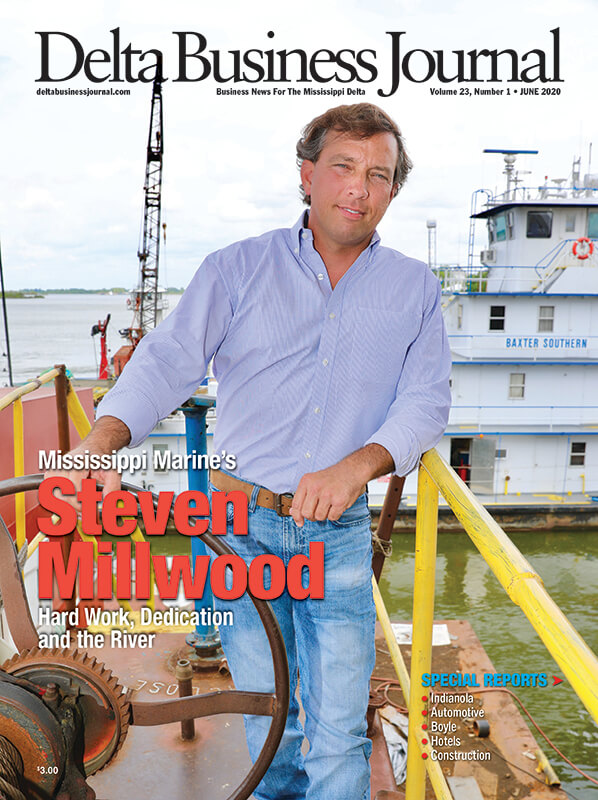

By Becky Gillette • Photography by Johnny Jennings

Especially during a worldwide pandemic, it is important that companies like Mississippi Marine Corp. in Greenville are able to operate vital shipyard repair services that facilitate the nation’s inland river transportation system.

“There are thousands of U.S.-flagged towboats moving more than 700 million tons of cargo a year on our nation’s waterways,” says Steven R. Millwood, president of Mississippi Marine. “A lot of people don’t realize that moving products by river barge is one of the most cost-effective ways to transport. A typical 15-barge tow can haul roughly 26,000 tons of cargo. To move that same amount of cargo by railway would take 200 rail cars or a little more than 1,000 tractor trailers. Studies have also shown that transporting by barge tends to be more fuel efficient and has a smaller environmental footprint.”

Shipyard workers have been named essential employees by the Department of Homeland Security’s Cybersecurity and Infrastructure Security Agency during the coronavirus disease 2019 (COVID-19) epidemic. Millwood says this was very important because it meant their employees wouldn’t miss a paycheck, and it allows them to make repairs as fast as possible to get towboats or barges repaired and back on the river.

“We’ve been able to carry on like normal even through this pandemic,” says Millwood. “Thankfully, the impact of COVID-19 has been minimal so far. Out of our 101 employees. I’ve only had one employee test positive. He’s made a full recovery and returned to work. We started taking precautions early on, like disinfecting the restrooms and break rooms twice a day, taking each employee’s temperature before each shift and passing out literature on the pandemic.”

Greenville Port Director Tommy Hart says Millwood is a perfect example of a “hometown boy making good.”

“The young man who runs this company is very sharp, just who you would want to have running this important company that is one of the largest private employers in Washington County.”

Dennis “Dino” Ross, senior vice president of marine engineering, Magnolia Marine, admires that Millwood is open-minded and willing to listen to the customers.

“He tries to accommodate when and where he can but, at the same time, help make Mississippi Marine profitable,” says Ross. “Steven has brought some new ideas to a company that has been around a long time. I believe those ideas will help take Mississippi Marine to the next level.”

Ross says the shipyard industry is a dangerous business and, for the longest time, employees had little to no training or safety.

“Steven has implemented procedures, training and meetings to heighten safety consciousness not only his employees, but for customers awareness,” says Ross.

Millwood joined the company in 2007 as billing manager for the central yard office. He was named president in January 2016.

Central Yard Manager Barry Alderman says Millwood was just who was needed to take over the company.

“He was actually my assistant,” says Alderman. “I’m very proud of him. I hired him many years ago and they stole him from me at the head office. He is really smart and done a great job, so he has moved up quickly. He is very competent. He put together a safety program that is one of the best in the state, which has helped on our insurance premiums. He promotes people who are doing well. He recognizes quality and I could not ask for anyone to do a better job.”‘

Millwood in his office at Mississippi Marine Corporation in Greenville.

Many employees have been with Mississippi Marine for more than forty years.

Mississippi Marine was started by D. John Nichols in 1972 with three other partners. By 1996, Nichols had acquired the interests of the other partners. Nichols ran the company up until his death September 24, 2018, at which time his wife, Melinda Nichols, became CEO/owner.

“The towing industry as a whole has diminished over the years in the Greenville area,” says Millwood. “But under the leadership of Mr. Nichols, Mississippi Marine Corporation has not only survived, but expanded, as well. We have three yards spread across forty acres along the banks of Lake Ferguson. We have six dry docks ranging from 1,800 tons to 4,000-ton capacity. We recently purchased an 80-ton Link-Belt barge mounted crane. We have a full-service machine shop and offer complete mechanical, electrical and carpentry repair.”

Many employees have been working for Mississippi Marine for more than forty years. The company offers above-average wages and an excellent benefits package.

“I increased the employee base pay rates in January,” says Millwood. “In addition to the raise, we offer paid health insurance, ten days of vacation, a matching 401(k) plan, tenure pay and a safety bonus.”

The company is impacted by Mississippi River flooding, but is set up to handle it. “Flooding is an inconvenience for us, but it doesn’t shut us down,” says Millwood.

Their North Yard, Central Yard and South Yards are on barges so they fluctuate with the water level. The administrative office is two-story. All of the offices are located on the second floor and the first floor is used for storage. As long as the river stays below sixty feet, it won’t get into the second-floor offices. If the water does get above sixty feet, like it did in 2011, they have temporary offices set up on their quarter’s barge.

Both his parents are from the Delta. He and his parents moved from Moorhead to Greenville when he was three years old. Millwood graduated from St. Joseph High School and attended Mississippi Delta Community College and Mississippi State University.

When he was thirteen, he started working after school and on the weekends for his grandfather, Luther Oakes, at Port City Trucking and Oakwood Plantation, where his father and uncles also worked.

“I learned a lot about business and life following them around through my teenage years,” says Millwood. “I was fortunate that my grandfather was a hands-on teacher. It didn’t matter what it was, a backhoe, combine, spray rig. I can remember pulling loaded cotton trailers to the Winterville gin with his truck. I had just turned fourteen years old, with no driver’s license.”

When he asked his grandfather what made him so successful, he says, “Hard work and dedication. Never stop learning no matter how old you get.”

What Millwood has found throughout his career at Mississippi Marine is that a lot of the older professionals in the shipyard and towing industries are always willing to offer advice and to help out.

“It’s been really beneficial to me over the years to have access to people like John Provenza with Kirby Inland Marine, Tim Hovas of NewSouth Marine Construction and many other leaders in our industry,” says Millwood.

The things he likes best about his job are the people he works with, the different challenges every day and working on Lake Ferguson. The hardest part of his job is finding skilled labor.

“It’s becoming harder and harder to find qualified welders and fitters,” says Millwood. “We offer above-average wages and benefits. But, due to our geographical area, the labor pool is not what it used to be. I’ve partnered with Mississippi Delta Community College, The CAPPS Center and The Washington County Economic Alliance to help promote these skilled labor programs and jobs to high school students and other individuals looking for a career path. The jobs are here for them.”

While Greenville has its challenges, like any town, he enjoys living here among his close-knit family. His brother, his brother’s wife, his parents and Millwood all live in the same neighborhood.

“I’ve grown up in the Delta,” he says. “I know where every fishing hole and hunting spot is within a forty-mile radius. I can’t imagine living anywhere else.”

Mississippi Marine is a full-service shipyard that offers marine repair, new construction and vessel renovation services to the inland and offshore vessel community. It is spread across an area of more than thirty-five acres with over 3,500 linear feet of slack water frontage. In addition to working on various types of inland river barges, towboats, dredges, tank and hopper barges, and shift and harbor boats, the company also repairs offshore vessels and rigs.

It provides engine repowering, line boring, inerting, shifting, gas freeing, bilge cleaning, temporary fuel storage, and blasting and painting services. The company operates more than ten dry docks and floating cranes and employs marine diesel mechanics and certified welders. It also maintains machine and propeller shops.